Some Known Incorrect Statements About Waterproofing Auckland

Wiki Article

Waterproofing Auckland Things To Know Before You Buy

Table of ContentsThe Single Strategy To Use For Waterproofing AucklandNot known Factual Statements About Waterproofing Auckland The Facts About Waterproofing Auckland UncoveredSome Known Incorrect Statements About Waterproofing Auckland The Definitive Guide for Waterproofing Auckland

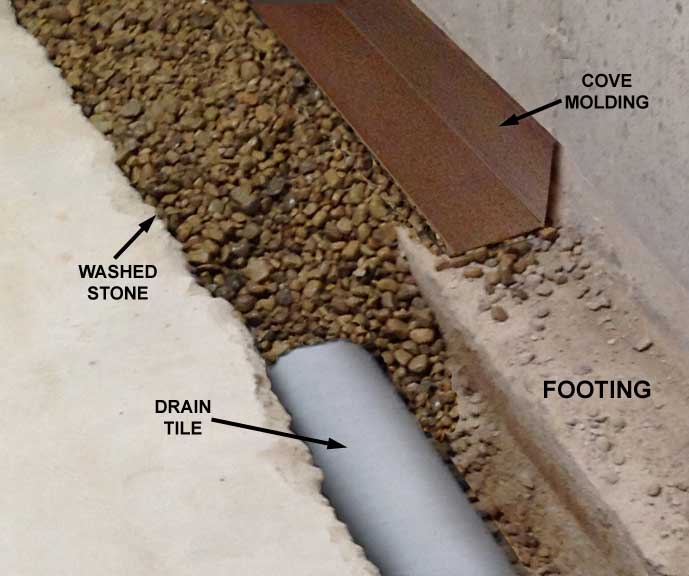

The joints of these pipes are maintained open. The gathering chambers are not glued from the inside or outside, to receive water from the surroundings.The underground water locates the means of least resistance with the filter media. The water is collected in the perforated pipelines with the filter media.

The procedure for the underground water storage tank is the very same as that of the basement, other than for the complying with points. Check this pipeline for its tightness prior to the waterproofing job treatment.

Getting My Waterproofing Auckland To Work

If white or colored joints are called for, after that the grey cement joints are raked, and also white cement or color concrete slurry is used with a little traverse the surface for joints of a coordinating color. The surface is again cleaned with sawdust. to remove excess white or shade concrete sticking to the polished china mosaic surface.Additional product is reduced off with a putty knife as well as a smooth upright joint is developed. Considering that the sealer is extremely expensive, use it.

The outer surface area of the sealant must offer a somewhat scooped surface in profile. Remove the covering up tape as well as tidy the surface with appropriate solvents. For water-proofing of the straight expansion joint, arrangements must begin from the R.C.C. phase of the structure. The complying with procedure should be observed. Inverted light beams are required to the location, for the development joint, side-by-side.

Socketing (stress grouting)' is a treatment to grout the concrete slurry by stress right into the permeable concrete member. Complying with a sequence of the work procedure.

The 6-Minute Rule for Waterproofing Auckland

Area 20mm (3/4) metal over the chiseled section, as a filter media. Take Care Of 25mm (1) G.I. socket over the steel, making use of rich cement mortar around the outlet as well as steel. Enable 1 day for the mortar to settle and also the tight fixing of the outlet. Wage grouting making use of a size G.I.5 to 2. 0m. Grouting should be done with concrete slurry of the needed thickness. For smooth flow, include 1 bag of concrete to 75 to 100 liters. If the waterproofing job procedure is refrained from doing appropriately, it can pose troubles. Repair work and upkeep of waterproofing can show very bothersome for the user.

is where the maximum water is utilized. Usually, the parent slab of the W.C. device has an I.W.C. Pan and also a concrete instance of dimension 0. 9m x 1. 2m x 0. 6m. This case is water-proofed after repairing the essential accessories such as P-trap, C.I. item, W.C. pan, and so on device can indicate the different factors of leakages, as listed here. The joint in between the C. 1/P. V.C. item and P trap. The joint in between the (tee) of external upright stack and P.V.C./ C.I. piece. The joint in between the P-trap and also I.W.C. frying pan. The joint between the flushing pipe as well as I.W.C frying pan. All these joints need to be secured with the proper sealant, at the particular stages throughout the implementation of the job.

Additionally, load all the voids in the floor covering of W.C. with concrete. Inspect the joint in between the P-trap as well as L.W.C. pan from above, by placing a hand into the trap. Seal this joint with M-seal, if it is partially open. Check the joint in between the flushing pipeline and also L.W.C. frying pan by damaging just one ceramic tile, fitted exactly over the junction.

The Buzz on Waterproofing Auckland

Open up the "Tee' of the vertical pile from the outside, with a ladder or zula and also observe the joint of C.I. piece and Tee' with find out torchlight as well as seal it appropriately. If leakage still continues, break open the hidden flushing G.I. pipe as well as check if it is leak-proof. Replace the dripping pipe/G. I.

If this does not stop the leak, break open the complete system and also inspect the joint at the P-trap and also C.I./ P.V.C. pipe. Do the new waterproofing job procedure totally with utmost treatment. Typically, 90% of leaks stop, if we bring out the repair as stated above, in the initial four factors.

like the container drainpipes, for their water tightness. This can be examined by stopping the operation of the laundry hand container and maintaining these lines completely dry as well as running them again after 4-5 days. If the leakages completely dry out and start, the resource is via these lines. Burst the lines and find the source as well as replace the affected part.

If leaks still persist, try socketing and grouting of cement slurry in the afflicted section. Ultimately, damage open the restroom waterproofing work procedure as well as re-do it carefully. A typical as well as successful technique check over here for treating minor leakages is to deal with the damaged part with concrete slurry. Use the cement slurry from the top and also allow it permeate in the fractures with the top part.

Rumored Buzz on Waterproofing Auckland

Check the damaged portion of the balcony utilizing a wooden club and examine if it has peeled. Eliminate the loose part with a chisel and also hammer. Re-do it thoroughly. If the leak is from the corners or from the parapet wall surface, after that his response fill all the fractures after damaging it open with cement.Some chemicals are advised for combining with cement, at the time of concreting. The typical technique of brickbat coba is still one of the most popular of water-proofing technique in India. Waterproofing substances are typically readily available in powder and liquid kind, as they serve the double objective of waterproofing job procedure as well as warmth protecting.

Make certain that the socketing is done before the skim coat job. Ensure that there is no leakage from the bathroom W.C. piece once the socketing is done. Ensure that the traps and also launch pipes are repaired effectively before the brickbat coba coat. Make sure that all the brickbats are well-soaked in water, prior to usage.

Maintain an appropriate space in between the brickbats. Examine the incline of the brickbat coat, towards the catch. Guarantee that the water-proofing substance is blended in the mortar, for every single phase of work. The topcoat must be performed in one stroke, without any joints. Ensure proper completing near traps as well as spouts.

Report this wiki page